Description

Exceptionally suitable for work on wear-resistant coatings and for hard facings made of tungsten carbide, chromium carbide, titanium carbide, etc. Particularly recommended for work on materials used for aircraft engine construction, e.g. Hastelloy, Inconel and titanium/titanium alloys. Also highly suitable for work on extremely hard materials such as tungsten carbide, glass, ceramics, enamel, stone and GRP/CRP.

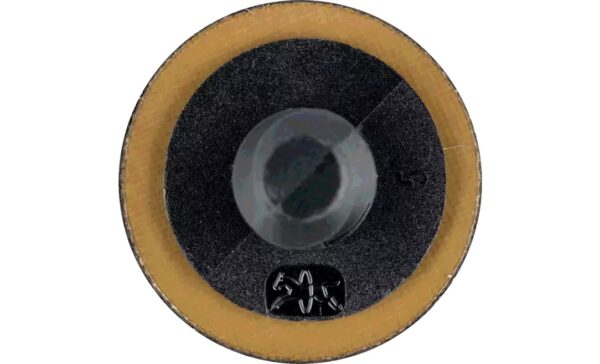

Sizes: 25mm, 38mm, 50mm, 75mm

Mounting systems: CD, CDR

Abrasive types: Diamond

Grits: D251 (P60), D126 (P120), D76 (P220)

Advantages:

- Quick tool changes

- Simple handling and low-vibration working

- No operational disruptions caused by sticking, slipping or disengaging

Materials that can be worked:

- Cobalt-based alloys

- Other non-ferrous metals

- High-temperature-resistant materials

- Nickel-based alloys (e. g. Inconell and Hasteloy)

- Titanium

- Hard non-ferrous metal

- Titanium alloys

- Thermoplastics

- Fibre-reinforced duroplastics (GRP, CRP)

- Stone

Applications:

- Roughening

- Levelling

- Deburring

- Surface work

- Work on edges

- Sharpening

- Weld dressing

- Fine grinding in multiple steps

Drive types:

- Flexible shaft drive

- Straight grinder

- Angle grinder

- Cordless angle grinder

Reviews

There are no reviews yet.